-

Timbers

-

-

Important

- All western red cedar timbers are appearance grade only and not intended for structural use.

*1 Coat Low Lustre Alkyd Oil must be top coated within 30 days.

Timbers

Clean & Bright / S4S

| NOMINAL SIZE | ACTUAL SIZE | Surfacing |

|---|---|---|

| 3 x 3 | 2-1/2” x 2-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 3 x 4 | 2-1/2” x 3-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 3 x 6 | 2-1/2” x 5-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 3 x 8 | 2-1/2” x 7-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 3 x 10 | 2-1/2” x 9-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 3 x 12 | 2-1/2” x 11-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 4 x 4 | 3-3/8” x 3-3/8” |

Resawn Clean and Bright or Smooth S4S

|

| 4 x 6 | 3-1/2” x 5-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 4 x 8 | 3-1/2” x 7-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 4 x 10 | 3-1/2” x 9-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 4 x 12 | 3-1/2” x 11-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

|

6 x 6

|

5-1/2” x 5-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 6 x 8 | 5-1/2” x 7-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 6 x 10 | 5-1/2” x 9-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 6 x 12 | 5-1/2” x 11-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 6 x 14 | 5-1/2” x 13-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 6 x 16 | 5-1/2” x 15-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 8 x 8 | 7-1/2″ x 7-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 8 x 10 | 7-1/2″ x 9-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 8 x 12 | 7-1/2″ x 11-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

|

10 x 10

|

9-1/2″ x 9-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

|

10 x 12

|

9-1/2″ x 11-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

| 12 x 12 | 11-1/2″ x 11-1/2″ |

Resawn Clean and Bright or Smooth S4S

|

Yard Rough

*Please note – Yard rough timbers have a ¼” tolerance from full dimension

| NOMINAL SIZE | ACTUAL SIZE | Surfacing |

|---|---|---|

|

3 x 3

|

2-3/4″ x 2-3/4″

|

Yard Rough

|

|

3 x 4

|

2-3/4″ x 3-3/4″

|

Yard Rough

|

|

3 x 6

|

2-3/4″ x 5-3/4″

|

Yard Rough

|

|

3 x 8

|

2-3/4″ x 7-3/4″

|

Yard Rough

|

|

3 x 10

|

2-3/4″ x 9-3/4″

|

Yard Rough

|

|

3 x 12

|

2-3/4″ x 11-3/4″

|

Yard Rough

|

| 4 x 4 |

3-3/4″ x 3-3/4″

|

Yard Rough

|

|

4 x 6

|

3-3/4″ x 5-3/4″

|

Yard Rough

|

|

4 x 8

|

3-3/4″ x 7-3/4″

|

Yard Rough

|

|

4 x 10

|

3-3/4″ x 9-3/4″

|

Yard Rough

|

|

4 x 12

|

3-3/4″ x 11-3/4″

|

Yard Rough

|

| 6 x 6 |

5-3/4″ x 5-3/4″

|

Yard Rough

|

|

6 x 8

|

5-3/4″ x 7-3/4″

|

Yard Rough

|

|

6 x 10

|

5-3/4″ x 9-3/4″

|

Yard Rough

|

|

6 x 12

|

5-3/4″ x 11-3/4″

|

Yard Rough

|

|

6 x 14

|

5-3/4″ x 13-3/4″

|

Yard Rough

|

|

6 x 16

|

5-3/4″ x 15-3/4″

|

Yard Rough

|

|

8 x 8

|

7-3/4″ x 7-3/4″

|

Yard Rough

|

|

8 x 10

|

7-3/4″ x 9-3/4″

|

Yard Rough

|

|

8 x 12

|

7-3/4″ x 11-3/4″

|

Yard Rough

|

|

10 x 10

|

9-3/4″ x 9-3/4″

|

Yard Rough

|

|

10 x 12

|

9-3/4″ x 11-3/4″

|

Yard Rough

|

|

12 x 12

|

11-3/4″ x 11-3/4″

|

Yard Rough

|

Timber Guidelines

- Checks

- Separation of the wood normally occurring across or through the rings of annual

growth and usually as a result of seasoning - Seasoning checks not limited, through checks at ends are limited as splits

- Separation of the wood normally occurring across or through the rings of annual

- Splits

- A separation of the wood through the piece to the opposite surface or to an adjoining surface due to the tearing apart of the wood cells

- Equal in length to 1 ½ times the width of the piece

- Wane

- Bark or lack of wood from any cause, except eased edges, on the edge or corner of a piece of lumber

- Allowed up to ¼ the thickness, 1/6 width, and ¼ length

- Warp

- Any deviation from a true or plane surface including bow, crook, cup and twist or any combination thereof

- Medium warp allowed per table in grade rules book, up to 1 5/8” in 12” wide x 24’

long

- Stained Wood

- Discoloration through exposure to the elements is admitted in all grades of framing and sheathing lumber

- Including iron/chain stains from mill machinery

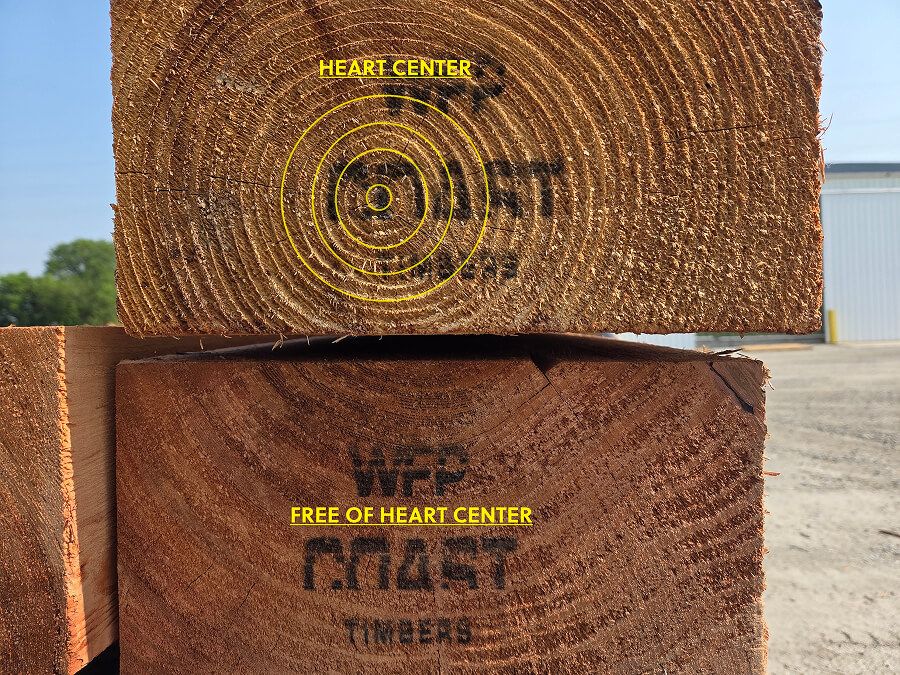

Checking

There are no limitations for checking on cedar or douglas fir timbers. Knowing where they most commonly occur can be useful when planning for installation.

Checking most commonly occurs on the face closest to the heart center of the timber.

Plan ahead to have the face closest to the heart center facing the house. This gives the greatest chance for the majority of checking to be opposite the side facing the street for a better aesthetic.

Our douglas fir timbers are all FOHC which is a great selling point for those looking for that cosmetic application.

When working with timber products, understand that they can and will check. This is a natural occurrence and timbers cannot be sorted or selected for checking characteristics.